Following the current trend of FMCG industries, which are increasingly committed to incorporate 4.0 technologies to the supply chain, from VM Systems, we are pleased to present our new automatic picking robot, created for one of the largest multinationals in the cava and wine production sector, Codorníu.

The customer needed an efficient solution that would allow them to handle all their products regardless of their shape and size, also whose dimensions would allow the maximum use of the space occupied in the plant.

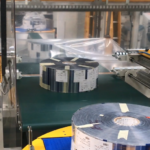

The project consisted of palletizing boxes of different sizes and shapes, depending on the orders they receive from their customers, and placing pallets as separators. The following video shows how it works in detail.

As we have already mentioned, it is a multifunctional equipment, with the versatility and capacity to handle any type of box regardless of its size and weight, adaptable to the different productions required by each industrial sector.

In addition, thanks to the ECO-Works (Stop & Go) system, we can control both the movements and the dead cycles of the equipment itself, whether robotic or not, to optimize production levels to the maximum.

Automating the picking or order preparation process has multiple organizational, productive and economic advantages in all companies, such as:

- Giving a fast and efficient response to our customers’ demand.

- Optimize the physical production space

- Reduction of direct and indirect costs in the preparation of orders.

- Easy absorption of peaks and production increases.

- Early detection of future work peaks, stock shortage problems, etc.

All these advantages translate into considerable operational cost savings for your company.

- Speed: Full automation of order picking is the solution if you handle many references or if orders are concentrated in specific time slots.

- Safety: The machines and robots that perform automatic picking tasks comply with stringent safety measures thanks to the sensor and detector technology they are equipped with.

- Accuracy: All systems are equipped with the latest software and sensor technology to operate with maximum accuracy. This reduces accidents with the palletized load.